Digital transformation in logistics is regarded as a major priority in the current context due to the impact of COVID-19 pandemic. Let’s find out with FPT the current situation and difficulties, as well as explore a variety of digital transformation solutions for the logistics industry via the below article.

1. What is digital transformation in logistics?

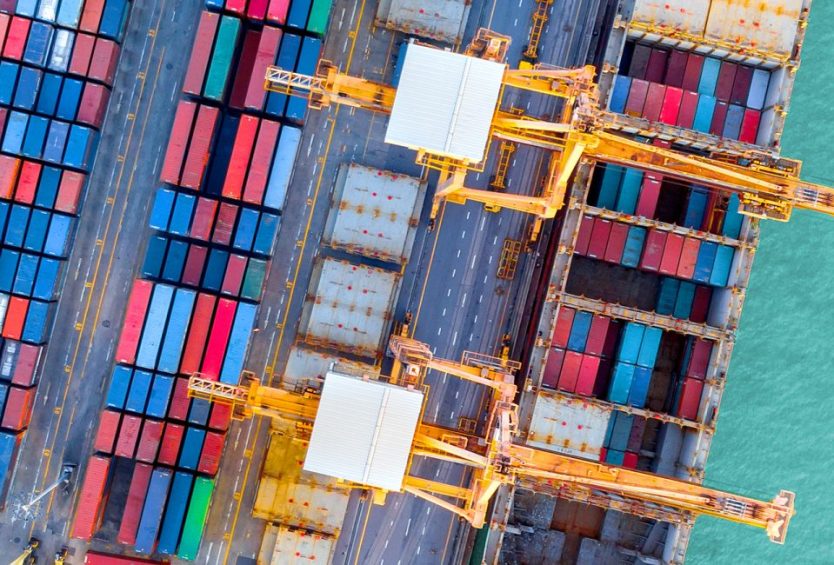

The process of utilizing technology to increase the productivity of production, supply, and transportation of products and services is referred to as digital transformation for businesses that offer logistics services. Logistics businesses need to digitize data, everage AI and Big Data technologies to analyze data, and create values by decreasing expenses for transportation, reducing risks, and raising revenue.

For example:

- Enterprises employ order management, warehouse management, and forwarding management software (FMS) (OMS and WMS). The logistics service operating procedure is thereby cost-optimized, enhancing the efficiency of order data management.

- Other physical retailers have improved their logistics by utilizing digital technology to hasten delivery times.

Both cases of digital transformation in logistics demonstrate the importance and necessity of implementing modern technology in business operations and brands and services.

Digital transformation in logistics helps decrease expenses for transportation, reduce risks, and raise revenue.

2. Benefits of digital transformation for the logistics industry

So how might the logistics sector benefit from digital transformation? Let’s investigate the advantages that digital transformation can bring to logistics organizations using FPT as stated below:

2.1. Automation saves money and time

Automation simplifies the overall flow of goods, ensures that cargos are trackable and arrive on schedule, and reduces other financial risks. When there is an issue that delays the transportation process, technology applications are employed to optimize resources and develop backup alternatives.

For example:

- Businesses can follow the route of goods being transported with the aid of online mapping software. This tool examines outside variables to determine the shortest route for transporting goods, allowing businesses to reduce material prices and delivery delays.

- The palletizing robot will make sure that all the goods are prepared and packed for shipment. As a result, businesses can reduce labor expenses by speeding up the loading and unloading of goods.

2.2. Increase the capacity to monitor the order process

Businesses are able to track the actual transport time of their goods created by technological applications. Since parameters and data are provided in detail from beginning to end, businesses may completely foresee any dangers associated with order progress.

Additionally, digital transformation in logistics enables logistics companies to reduce the length of the transportation route by maximizing the time spent loading and unloading goods. For this reason, the order progress is likewise as optimal as possible.

2.3. Easily track the status of your shipments

The Internet of Things can boost delivery management in a number of ways, of which business managers can trace shipments all the route to their destination according to connected RFID tags and GPS sensors.

Moreover, logistics managers can also get real-time location data from connected sensors to guarantee that changes in the weather or other environmental factors won’t delay deliveries.

2.4. Increase the level of transparency in shipping activities

Business managers seek to integrate IoT solutions for logistics in order to accomplish the digital transformation in logistics that increases transparency of the delivery process. Being able to track products from the warehouse to the customer’s door increases managers’ confidence that all stages of the supply chain are completed smoothly.

Also, it contributes to win customers’ trust in the brand and support the agent to save time since the customers are likely to no longer request delivery status updates from customer service.

2.5. Optimize internal operations

It has been proven that the more openly and transparently departments communicate with one another, the more mistakes that the businesses can avoid. This helps increase efficiency in the supply chain by:

- Make decisions to implement a highly efficient technology for logistics’ digital transformation: Businesses are required to conduct both impartial and targeted supplier research to avoid selection bias.

- Verify that the current technology can be integrated with more modern solutions: Enable automated data exchange and in-the-moment departmental dialogue.

- Strategic thinking: With more time saved through automated procedures. When unexpected occurrences occur, staff members can concentrate on strategy, customers, and developing solutions.

3. Actual situation of digital transformation in the logistics industry

Vietnam’s logistics is a competitive market that is estimated to be worth about 40-42 billion USD per year. Therefore, in order to strengthen the position, businesses are encouraged to strongly take advantage of digital transformation. These practical examples show the reality of digital transformation in logistics:

- Saigon Newport Corporation is a pioneer in digital transformation in logistics.

Tan Cang Cai Mep International Port set a record for mother ship handling from 14,235 TEU to 15,615 TEU in 2021, with a handling capacity of 238.08 containers/hour, despite the challenges brought on by the COVID-19 epidemic. Through 2 million TEU, One Columba has continued to exceed the volume of cargo. Additionally, it accounts for more than 55% of the market share for import and export containers across all of the nation’s seaports.

- With double-digit volume growth in all three areas, Gemadept Corporation likewise overcame a difficult year.

Its overall production was expected to be 2.7 million TEUs last year, an astounding increase of 53%. This accomplishment is attributable to the group’s digitalization of port operations and logistical procedures, which has helped clients save money and make better use of their time and resources.

- Other logistics enterprises.

DHL, FedEx, Maersk Logistics, APL Logistics, CJ Logistics, and KMTC Logistics are among the other digital transformation companies in the logistics sector who are joining the race. They believe that digital transformation is the key to overcome challenges, compete, and grow.

However, only around 40% of companies in this industry are now undergoing digital transformation.

Director of Vietrade Vu Ba Phu mentioned at a recent policy dialogue on logistics held by the Vietnam Trade Promotion Agency (Vietrade) and the Korea Trade and Investment Promotion Agency (KOTRA) in Hanoi that the country’s logistics industry is facing struggles due to economic growth, particularly in the import and export sectors.

He added that an action plan to boost competitiveness and the development of Vietnam’s logistics industry by 2025 has been carried out in order to lower costs and increase efficiency in this area. The Fourth Industrial Revolution has led to the transformation of traditional logistics centers into new generation centers using high technology, he said.

Dinh Huu Thanh, the CEO of Bee Logistics Corporation, advised that the Government consider logistics as a supporting business and therefore create more appropriate policies, while continuing to modernize management in this field.

4. Opportunities and challenges of digital transformation in the logistics industry

Given the aforementioned situation, enterprises engaged in digital transformation in logistics must have distinct perspectives on opportunities as well as problems when putting such initiatives into practice. Let’s refer to the opportunities and difficulties listed below from the viewpoint of FPT:

4.1. Opportunities

As the key sector in the economy, logistics is the cornerstone of international trade. Technology advancements, company growth, complicated supply chains, and growing rivalry have forced managers to raise operational standards to differentiate themselves from their competitors and succeed in the marketplace.

The World Economic Forum forecasts that by 2025, the effectiveness of digitization in supply chain management will threaten more than $1.5 trillion in traditional logistics revenue. At the same time, digital transformation solutions for logistics increase sharing and collaboration, make internal operations more flexible, and need less effort to complete other complicated tasks. The main issues with vertical globalization are addressed by digital solutions in the logistics sector (e.g. more frequent changing needs, increased security and compliance rigor, etc.). There are several ground-breaking prospects for digital transformation in logistics present now to support organizations in thriving, particularly to overcome challenges and recover from the pandemic:

- Improve specialized air cargo capacity:

The aviation industry has reconfigured its fleets to precisely meet the requirements of air transportation.

- Strengthen goods inspection and cross-border control processes:

Temporary trade embargoes and export limitations on sensitive commodities have been implemented by governments in response to the crisis (such as medical

supplies and pharmaceuticals). Long-term logistical costs may rise as a result of more stringent border controls and procedures brought on by worries about disease transmission.

- The rise of technology and e-commerce:

A technological revolution has been taking place in logistics. Companies with great digital skills have an advantage when it comes to providing goods visibility/traceability and conducting commerce online.

Investments in technology, including the Internet of Things (IoT), cloud computing, automation, and data analytics, will be necessary to achieve this. Besides, robots, drones, and autonomous trucks may eventually lessen the possibility of a manpower shortage for logistics companies in the long term.

- Restructure global value chains:

Particularly in the East Asia Pacific area, the pandemic has revealed the susceptibility of broad and complex value chains to production disruptions. As a response, many of these supply chains may become more compact or diverse by relying on other partners (such as close recruiting) or by stepping up efforts to reintroduce the strategic value chain to the market. housing (such as subletting).

A shorter supply chain may benefit nations such as Colombia, India, and Mexico, which have strong manufacturing sectors and welcoming export policies, partially displacing China in the medium run. In order to reduce time to market, there may also be a tendency to locate additional storage space or dry docks close to incoming demand.

Depending on the country and sub-sector, recovery prospects will differ: Given the diversity of the logistics industry, the prospects for recovery will differ depending on how long the current economic crisis lasts and how long the next one lasts. Large corporations having diversified enterprises (such as many clients, serving various sectors in various countries/states) will be better able to overwhelm the struggles.

4.2. Challenges

Over the past year, the transportation and logistics sector, like all other sectors, has suffered immensely. With product migrations stalled, fewer bills of sale, and growing pressure to go online, the industry suddenly finds itself surrounded by changes, challenges, and expectations.

In actuality, the majority of these issues are caused by the absence of a cutting-edge and trustworthy logistics digital platform, which makes it impossible for executives to run their businesses efficiently in terms of both time and money. Specifically, there are 5 primary challenges:

- Logistics and transport have not yet been integrated:

There is access to extensive supply chain, transportation, and logistics industries in a buying and selling industry that is driven by digital technology in order to meet order requirements and transfer products rapidly and affordably across borders.

With the emergence of global trade, traditionally uncompetitive, craft-based activities are now a threat to businesses that don’t make an attempt to disrupt them by opting to digitize logistics and transportation and provide flexibility to their business models.

- Ineffective use of abundant data due to the lack of knowledge:

With the current commercial boom in mind, this business generates and keeps enormous amounts of data and information. Nevertheless, it becomes challenging to obtain this data when it is segmented and stored in different locations. This, together with human data entry and processing, results in inaccurate outputs that defeat the objective of enhancing the client experience.

Digital logistics solutions connect all the many sources on a single integrated digital logistics system in addition to efficiently tracking and managing this data. Business executives are also assisted by digitization in logistics and supply chain management to adhere to new data management standards and satisfy customer expectations.

- Lack of resiliency and process automation:

Labor-intensive logistics and internal transportation operations led by people are not only time-consuming but also error-prone and inefficient, in which the pandemic is also the last gasp for the L&T sector.

Accordingly, process automation through transportation and logistics digitalization becomes crucial to obtaining a comprehensive understanding of corporate processes and enabling omnichannel consumer engagements. A more adaptable and flexible company model will arise from the implementation of digital solutions for automation and logistics.

- Over-reliance on aging systems:

Operations are slowed down by aging systems, which also reduce productivity and raise technical liabilities. Thus, ensuring company continuity and future-proofing your model are important to scale without risk.

The L&T sector must embrace contemporary business operations and processes. It’s time to switch out paper for a revolutionary digital logistics platform that works nicely with existing systems.

- The lack of a migration management plan:

Although every strategy in terms of digital transformation has mobility at its core, as the number of devices requiring a connected experience increases, so too do process complexity, IT pain points, and competitive risk.

Furthermore, digital logistics solutions, particularly with an ever-increasing number of devices, not only power data warehouses but also render them unfeasible due to a lack of planning to manage mobility to deliver the anticipated ROI and stand out from the crowd.

5. Optimal digital transformation solutions in logistics

Today’s logistics units have more options than ever before. Here are some solutions that are currently being applied by businesses and have had great success.

5.1. Electronic air waybill:

IATA refers to the exchange of electronic data messages (EDI) in place of a paper air waybill as “e-AWB” when a contract for carriage is made. The implementation of e-AWB will increase output, boost dependability, speed up procedures, improve customer service, and cut expenses.

By the end of 2022, the industry is expected to have fully adopted eAWB, which will mean that all shipments will be made using this method solely, according to a target set by IATA in 2020.

5.2. AI and Machine Learning

The logistics industry will benefit enormously from AI and machine learning since these technologies make it easier for logistics companies to use and analyze data, find patterns, and subsequently enhance operations. While AI gathers data, machine learning analyzes massive volumes of data, completes repetitive jobs flawlessly, multitasks swiftly, works continuously, and never stops improving.

Models can be used for supply chain management, demand forecasting, production planning, and more. In other words, applying AI & ML may give companies the knowledge they need to lower risk, boost performance, and even save freight costs. According to the study and research, AI is expected to boost productivity by more than 40–45% by 2035.

5.3. Blockchain Deployment

The advantages of blockchain in logistics include unmistakable increases in transparency, strengthened relationships between companies, total payment security, improved management procedures, and lower expenses. Blockchain is an ideal tool for facilitating the tracking of products, international contracts, and payment processing due to its instructor-like functionality.

It is inevitable that logistics organizations will undergo digital transformation, in which the most prominent example of this is blockchain technology – A necessity for future warehouses and a competitive advantage today.

5.4. Cloud Technology Integration

Every aspect of a company is being revolutionized by cloud computing, but logistics is where this is most obvious. In order to anticipate and address issues before they happen, businesses all over the world are shifting away from antiquated technologies and manual methods.

Real-time information access provides organizations with numerous chances to boost productivity and offer consumers value-added services. The removal of different WMS and TMS Systems, enhanced equipment and usage patterns, access to real-time pricing and inventory, unified modeling in the appropriate shipping process.

5.5. Automatic Forklift

First and foremost, data is a requirement for autonomous driving. Autonomous vehicles gather information with its sensors in a similar way that humans do with our senses, which then pass the information to our brains for processing to make decisions.

Numerous cameras at the front, back, and sides of the vehicle scan the whole area around it, instantaneously identifying potential obstructions and measuring their distances and speeds as they approach. The on-board computer decides how to maneuver the car based on this information.

Although automated driving is frequently seen from the driver’s point of view, the development of automated technology and the digital transformation of logistics are especially important for the industry. Firstly, due to the critical need for truck drivers.

Second, it can improve the efficiency, safety, and sustainability of logistical operations. Hence, there are various concepts and approaches about how to do this in practice.

Conclusion

The logistics industry has expanded and developed rapidly over the last two years, which will continue and advance in 2022. The way we work in logistics this year will be significantly impacted by digitization and sustainability.

Numerous innovations have been launched, and new technologies will continue to evolve, simplifying operations and boosting supply chains’ stability globally. By 2022, the entire logistics sector will establish a ground-breaking roadmap thanks to a significant sustainable trend.

The goal is to keep logistics profitable while bringing it into harmony with the environment. As a result of the huge upheaval brought on by digitization and climate change, successful market actors that quickly adapt to it and actively take part in the introduction of new technologies will emerge.

To sum up, digitization is the future of transportation and logistics, and moving to a centralized digital logistics platform is simple. When FPT is involved, digital transformation in logistics may be straightforward, efficient, and simple to comprehend.